Example 1: Gear for Electric wheelchairs - Helical Gears

Example 1: Gear for Electric wheelchairs - Helical Gears

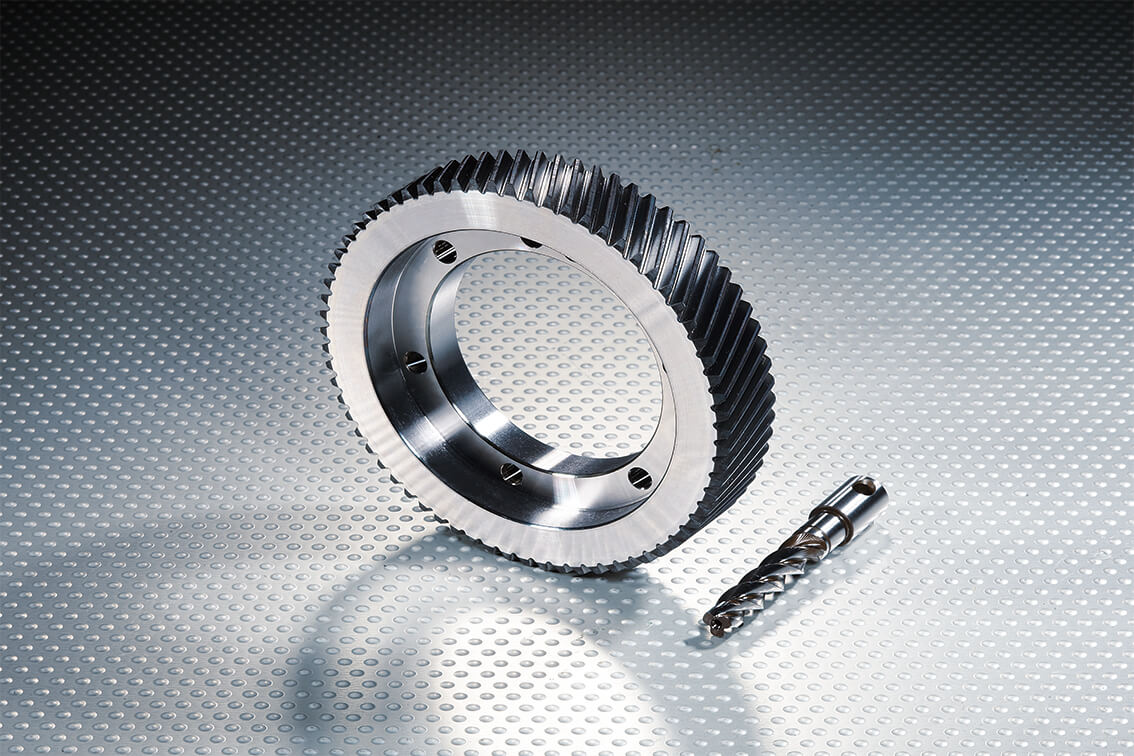

On a helical gear, the teeth' leading edges are not parallel to the axis of rotation but are set at an angle. Since the gear is curved, this angling makes the tooth shape a helix segment, and the teeth are longer and more durable than other types of gears. Helical gears can be meshed in parallel or crossed orientations. The teeth are meshed more slowly than spur gear teeth; therefore, the machine operation is smoother and quieter. Helical gears are often used in high-speed applications, or applications, in which the reduced noise level is required.

Wen-Hsiang machines high-precision helical gears for electric wheelchairs. Our helical gears are smooth and ensure the quiet operation of the wheelchairs.

| Steps | Measurement items | Dimensions |

| Raw metal inspection | Inspect whether the raw metal matches the description in the material certificate. | |

| Lathing | Dimensional Measurement | Diameter, bearing spacing, depth |

| Milling | Dimensional Measurement | Form and size measurement, compared with scanning and PCD results (pitch diameter, symmetry) |

| Rough hobbing | Gear Test | External tooth profile, lead, pitch, tooth span, tooth profile |

| Heat treatment | Hardness test | Tests for checking material characteristics, hardness, and metallographic examination |

| Grinding (Youdo) | Height measurement, surface roughness, inner diameter, outer diameter | |

| Skiving | Pitch |