Process Control Approach of Quality Control for Gears and Motor Shafts

Process Control Approach of Quality Control for Gears and Motor Shafts

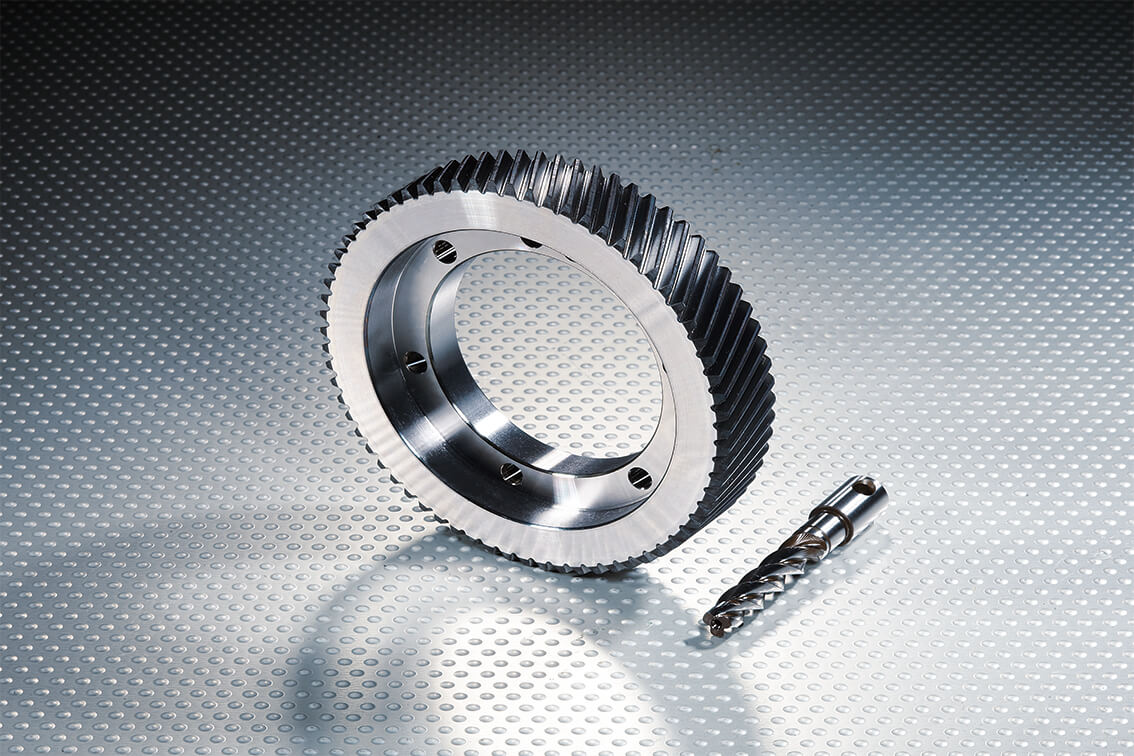

Quality is Wen-Hsiang's top priority. The quality of machined gears and motor shafts from Wen-Hsiang can reach JIS 0-2 levels (Japanese Industrial Standards B 1702). To ensure that our machining outcomes meet the quality required by the internal quality standard and the customer, we take the quality of our work seriously. Our quality control adopts a process control approach, which uses a specific processing sequence and closely monitors the work in each process.

For our gear and motor shaft machining, we usually follow the following procedure and JIS levels:

*Heat treatment is outsourced.

| Initial machining steps | Advanced machining steps | IS levels | Applications |

| Raw material quality inspection Lathing Milling |

Rough hobbing-> Finish hobbing* | 4-5 | Shafts, Gears |

| Rough hobbing-> Heat treatment-> Grinding (Youdo) -> Skiving | 1-2 | Shafts, Gears | |

| Rough hobbing-> Heat treatment-> Grinding (Youdo) -> Finish grinding | 0-1 | Gears |

*Not Wen-Hsiang's leading service